7 days free payment

7 days free paymentrefund after 7-14 days

100% genuine product

100% genuine product

High-speed steel boring machine Ø11.1 OSG 7511110 or also known as knife, product of the OSG brand specializing in providing prestigious cutting tools in the world. OSG product lines are manufactured according to a modern production line system, with many different types of coatings for high durability and good quality.

1. What is Ø11.1 OSG 7511110 high-speed steel boring machine?

Reaming is a method of fine machining holes after drilling, or after boring, turning with the characteristic that the machined surface coincides with the positioning surface of the tool, so it cannot correct the relative position deviation left by previous operations.

Ø11.1 OSG 7511110 high-speed steel boring machine or often called high-speed steel boring cutter, specialized for CNC machining machines such as lathes, milling machines...

Reamer is used to drill large holes with low cutting thickness to machine precision matching holes up to IT5 with high surface gloss.

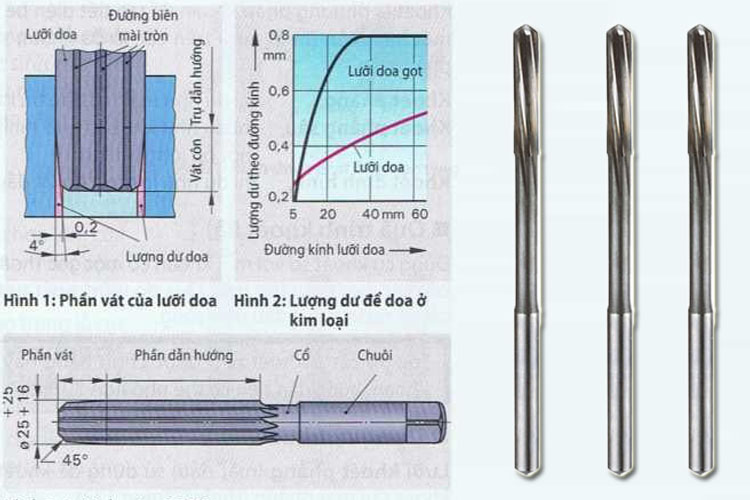

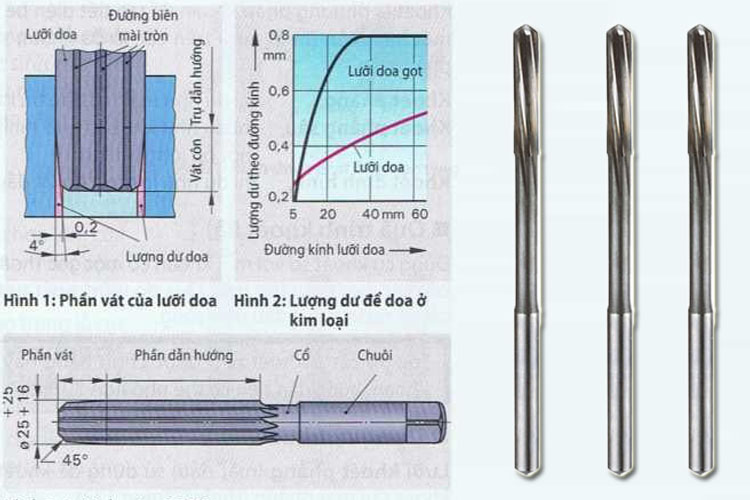

The machining and cutting process of mui aa OSG is mainly made by the beveled edge of the reamer blade, the cutting edge creates a hole with the correct circumference, shape accuracy and surface finish.

OSG reamer used in machining of CNC machines

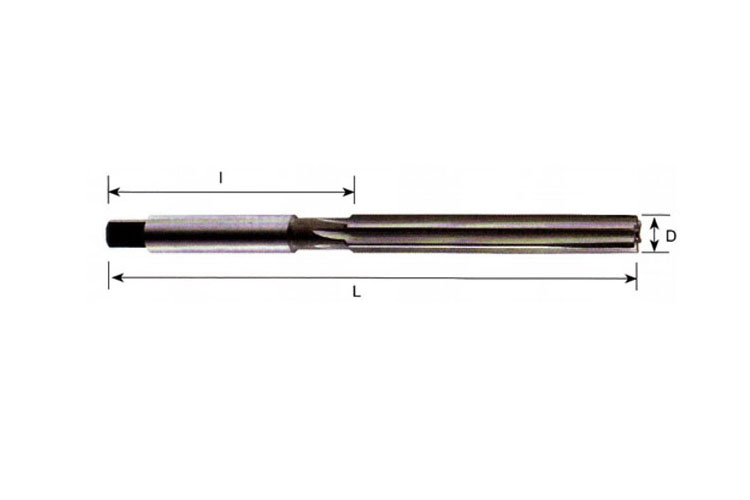

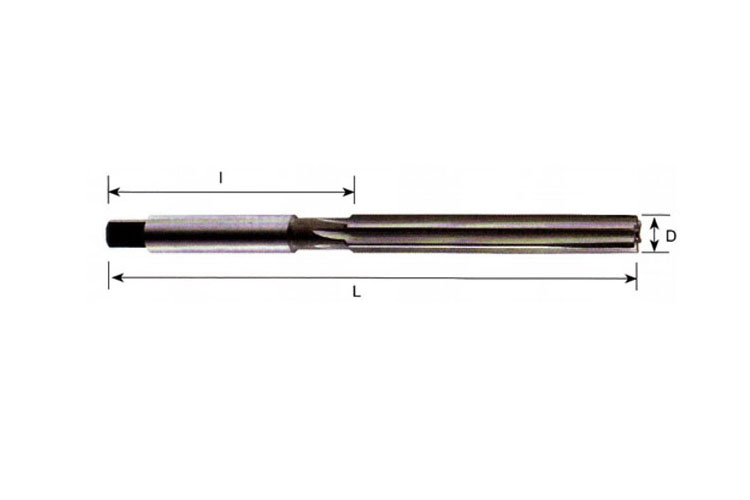

2. Structure of Ø11.1 high-speed steel boring machine OSG 7511110

The Ø11.1 high-speed steel boring machine OSG 7511110 is made of high-speed steel with 4 main parts: the chamfer, the guide, the neck and the reamer shank.

- The chamfer: used to center the hole before cutting and machining.

- The guide: after centering with the chamfer, the reamer will perform cutting

- The neck: the longer this is, the better the ability to increase the depth for boring and cutting.

- The reamer shank: to hold the clamps on CNC machines to clamp the reamer to help the reamer work effectively.

Outstanding features of the reamer

Made from HSS high speed steel material, after processing The surface by coating TiN (Titanium Nitri) boring machine high-speed steel will increase smoothness and increase product durability by 3 times.

Advantages of OSG boring machine:

- The 45-degree spiral groove when machining achieves extremely good gloss.

- Used to ream blind holes that require reaming the entire hole.

- Can be used for both blind holes or through holes.

- When there are many intersecting holes, the reaming does not leave burrs on the edge (intersection).

High-speed steel boring machine Ø11.1 OSG 7511110 or also known as knife, product of the OSG brand specializing in providing prestigious cutting tools in the world. OSG product lines are manufactured according to a modern production line system, with many different types of coatings for high durability and good quality.

1. What is Ø11.1 OSG 7511110 high-speed steel boring machine?

Reaming is a method of fine machining holes after drilling, or after boring, turning with the characteristic that the machined surface coincides with the positioning surface of the tool, so it cannot correct the relative position deviation left by previous operations.

Ø11.1 OSG 7511110 high-speed steel boring machine or often called high-speed steel boring cutter, specialized for CNC machining machines such as lathes, milling machines...

Reamer is used to drill large holes with low cutting thickness to machine precision matching holes up to IT5 with high surface gloss.

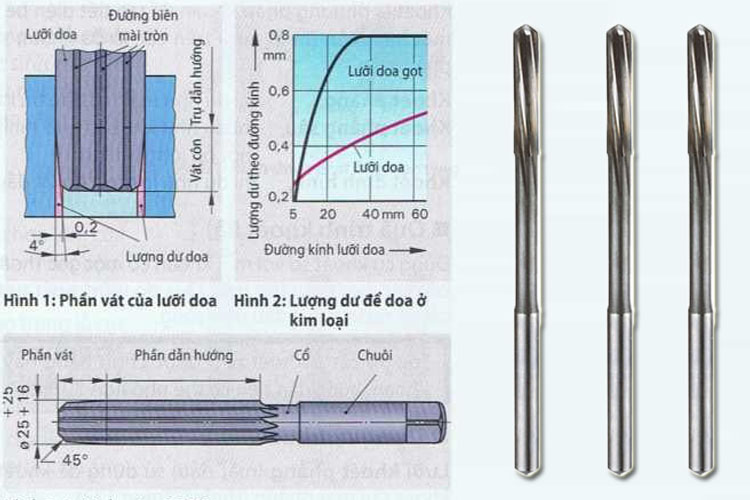

The machining and cutting process of mui aa OSG is mainly made by the beveled edge of the reamer blade, the cutting edge creates a hole with the correct circumference, shape accuracy and surface finish.

OSG reamer used in machining of CNC machines

2. Structure of Ø11.1 high-speed steel boring machine OSG 7511110

The Ø11.1 high-speed steel boring machine OSG 7511110 is made of high-speed steel with 4 main parts: the chamfer, the guide, the neck and the reamer shank.

- The chamfer: used to center the hole before cutting and machining.

- The guide: after centering with the chamfer, the reamer will perform cutting

- The neck: the longer this is, the better the ability to increase the depth for boring and cutting.

- The reamer shank: to hold the clamps on CNC machines to clamp the reamer to help the reamer work effectively.

Outstanding features of the reamer

Made from HSS high speed steel material, after processing The surface by coating TiN (Titanium Nitri) boring machine high-speed steel will increase smoothness and increase product durability by 3 times.

Advantages of OSG boring machine:

- The 45-degree spiral groove when machining achieves extremely good gloss.

- Used to ream blind holes that require reaming the entire hole.

- Can be used for both blind holes or through holes.

- When there are many intersecting holes, the reaming does not leave burrs on the edge (intersection).

Boring machine for high speed steel Ø11.1 OSG 7511110

High-speed steel boring machine Ø11.1 OSG 7511110 or also known as knife, product of the OSG brand specializing in providing prestigious cutting tools in the world. OSG product lines are manufactured according to a modern production line system, with many different types of coatings for high durability and good quality.

1. What is Ø11.1 OSG 7511110 high-speed steel boring machine?

Reaming is a method of fine machining holes after drilling, or after boring, turning with the characteristic that the machined surface coincides with the positioning surface of the tool, so it cannot correct the relative position deviation left by previous operations.

Ø11.1 OSG 7511110 high-speed steel boring machine or often called high-speed steel boring cutter, specialized for CNC machining machines such as lathes, milling machines...

Reamer is used to drill large holes with low cutting thickness to machine precision matching holes up to IT5 with high surface gloss.

The machining and cutting process of mui aa OSG is mainly made by the beveled edge of the reamer blade, the cutting edge creates a hole with the correct circumference, shape accuracy and surface finish.

OSG reamer used in machining of CNC machines

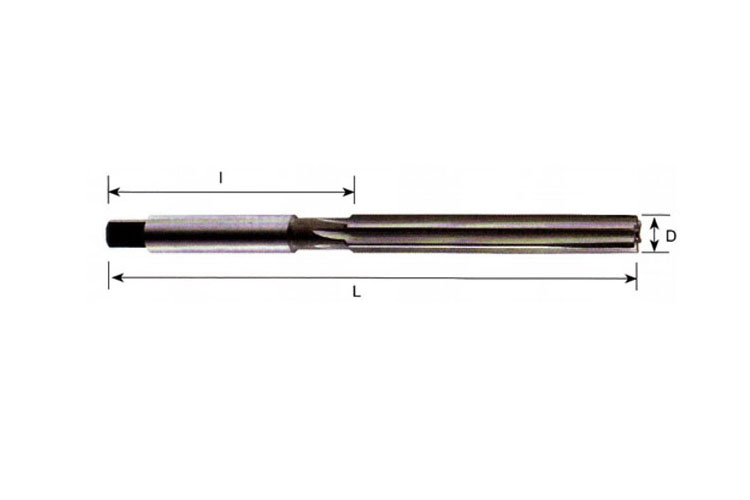

2. Structure of Ø11.1 high-speed steel boring machine OSG 7511110

The Ø11.1 high-speed steel boring machine OSG 7511110 is made of high-speed steel with 4 main parts: the chamfer, the guide, the neck and the reamer shank.

- The chamfer: used to center the hole before cutting and machining.

- The guide: after centering with the chamfer, the reamer will perform cutting

- The neck: the longer this is, the better the ability to increase the depth for boring and cutting.

- The reamer shank: to hold the clamps on CNC machines to clamp the reamer to help the reamer work effectively.

Outstanding features of the reamer

Made from HSS high speed steel material, after processing The surface by coating TiN (Titanium Nitri) boring machine high-speed steel will increase smoothness and increase product durability by 3 times.

Advantages of OSG boring machine:

- The 45-degree spiral groove when machining achieves extremely good gloss.

- Used to ream blind holes that require reaming the entire hole.

- Can be used for both blind holes or through holes.

- When there are many intersecting holes, the reaming does not leave burrs on the edge (intersection).

7 days free payment

7 days free paymentrefund after 7-14 days

100% genuine product

100% genuine product

Add to cart successfully!

Add to cart successfully!